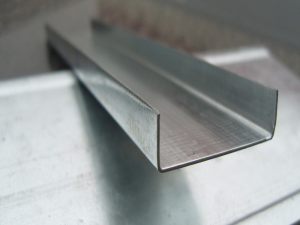

Nerjaveèi asye wonn Bar

Deskripsyon

Pwosedi pwodiksyon:

Eleman kri (C, Fe, Ni, Mn, Cr ak Cu), fonn nan lengote pa AOD finery, cho woule nan sifas nwa, marinated nan likid asid, poli pa otomatikman machin ak koupe an moso.

Estanda:

ASTM A276, A484, A564, A581, A582, EN 10272, JIS4303, JIS G 431, JIS G 4311 ak JIS G 4318

Dimansyon:

Woule cho: Ø5.5 a 110mm

Fwad-trase: Ø2 a 50mm

fòje: Ø110 a 500mm

Longè nòmal: 1000 a 6000mm

Tolerans: h9 & h11

Karakteristik:

Bèl aparans nan gloss pwodwi woule frèt

Bèl fòs tanperati ki wo

Bèl travay-di (apre yo fin trete fèb mayetik)

Solisyon eta ki pa mayetik

Apwopriye pou achitekti, konstriksyon ak lòt aplikasyon

Aplikasyon:

Konstriksyon jaden, endistri bati bato

Materyèl dekorasyon ak tablo afichaj piblisite deyò

Otobis andedan ak deyò anbalaj ak bilding ak sous dlo

Ranp, electroplating ak electrolyzing pandantif ak manje

Kowozyon- ak fwotman-gratis satisfè kondisyon espesifik nan divès kalite machin ak jaden pyès ki nan konpitè

Enfòmasyon de baz

Aplikasyon komen

316 klas Nerjaveèi asye ba wonn gen yon seri gwo aplikasyon, yo ka koupe, fòme & koube, file, komanse fouye ak soude pou itilize nan:

Aplikasyon Marin

Anviwònman chimik

Aks & Arbr

Griy ak griyaj

Ekran

Sekirite griyaj

Jeni jeneral

Preparasyon sifas ak penti

Kontrèman ak asye grav, chimi asye pur vle di pwosesis ak metòd pou pwoteje ak fini asye pur 316 klas yo diferan anpil ak asye modere.Pifò fini sifas pou asye pur yo pral mekanikman (Polisaj) oswa chimikman (Pasivasyon) aplike.Fini sifas ki kòrèk la pral gen gwo enpak sou pèfòmans ak aparans asye pur ou a.

Youn nan konsiderasyon ki pi enpòtan pou pèfòmans ak aparans Nerjaveèi asye se pwòpte.Sifas yo dwe kenbe gratis nan patikil lòt metal espesyalman alyaj oswa asye kabòn.Timber tou gen kontaminan ki pral leech ak tach asye pur.

Klas nan ba asye pur

| Klas | Klas | % konpozan chimik | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Lòt | ||

| 301 | 1.431 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | ≤0.10 | - |

| 304 | 1.4301 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - |

| 304L | 1.4307 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - |

| 304H | 1.4948 | 0.04-0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - |

| 309 | 1.4828 | ≤0.20 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - |

| 309S | * | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - |

| 310 | 1.4842 | ≤0.25 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - |

| 310S | * | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - |

| 314 | 1.4841 | ≤0.25 | 23.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | 1.50-3.00 | - | - | - |

| 317 | * | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - |

| 317L | 1.4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - |

| 321 | 1.4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 |

| 321H | * | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 |

| 347 | 1.455 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10 * C% -1.10 |

| 347H | 1.494 | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10 * C% -1.10 |

| 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0.040 | ≤0.020 | - | ≤1.00 | - | ≤0.030 | Ti6(C+N)~0.50 Nb:0.17 |

| 410 | 1Cr13 | 0.08-0.15 | 11.50-13.50 | 0.75 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 420 | 2Cr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 430 | 1Cr17 | ≤0.12 | 16.00-18.00 | - | ≤1.0 | ≤0.040 | ≤0.030 | - | ≤1.0 | - | - | - |

| 416 | Y1Cr13 | ≤0.15 | 12.00-14.00 | 3) | ≤1.25 | ≤0.060 | ≥0.15 | - | ≤1.00 | - | - | - |

| 444 | S44400 | ≤0.025 | 17.50-19.50 | 1 | ≤1.00 | ≤0.040 | ≤0.030 | 1.75-2.5 | ≤1.00 | - | 0.035 | Ti+Nb:0.2+4(C+N)~0.80 |

| 446 | S44600 | ≤0.20 | 23.00-27.00 | 0.75 | ≤1.5 | ≤0.040 | ≤0.030 | 1.50-2.50 | ≤1.00 | - | ≤0.25 | - |

| 431 | 1Cr17Ni2 | ≤0.20 | 15.00-17.00 | 1.50-2.50 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤0.80 | - | - | - |

| 630 | 17-4PH | ≤0.07 | 15.00-17.50 | 3.00-5.00 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 17-7PH | ≤0.09 | 16.00-18.00 | 6.50-7.50 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | ≤0.50 | - | Al 0.75-1.50 |

| 632 | 15-5PH | ≤0.09 | 14.00-16.00 | 3.50-5.50 | ≤1.00 | ≤0.040 | ≤0.030 | 2.00-3.00 | ≤1.00 | 2.5-4.5 | - | Al 0.75-1.50 |

| 904L | N08904 | ≤0.02 | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | ≤0.045 | ≤0.035 | ≤1.00 | 0.1 | Cu: 1.0-2.0 | ||